Description and Current Mission

Description and Current Mission

Although there have been no completely new weapon designs assembled since 1991, technicians at Pantex continue to disassemble and reassemble existing weapons in connection with NNSA programs to evaluate, repair, modify, and certify them.

The Pantex Plant is located on 16,000 acres in the panhandle of Texas (hence "Pantex"), approximately 17 miles northeast of Amarillo. The facility is operated by Babcock & Wilcox Technical Services. Pantex currently employs about 3,300 people in support of NNSA activities.

Built by the U.S. Army in 1942, the site was originally a munitions plant for artillery shells and bombs. At the end of World War II, the Plant closed but was subsequently refurbished in 1951 to perform final nuclear weapons assembly work. Between 1965 and 1975, the Atomic Energy Commission (DOE's predecessor) consolidated various assembly, modification, and high explosive missions at Pantex from other sites in the nuclear weapons complex, leaving it as the only production plant in the United States where nuclear weapons are fully assembled and disassembled. Nuclear policy decisions and international treaties in the 1990s led to the requirement for Pantex to dismantle a portion of the large Cold War nuclear weapons stockpile. Plutonium pits from these dismantled weapons are currently stored at Pantex.

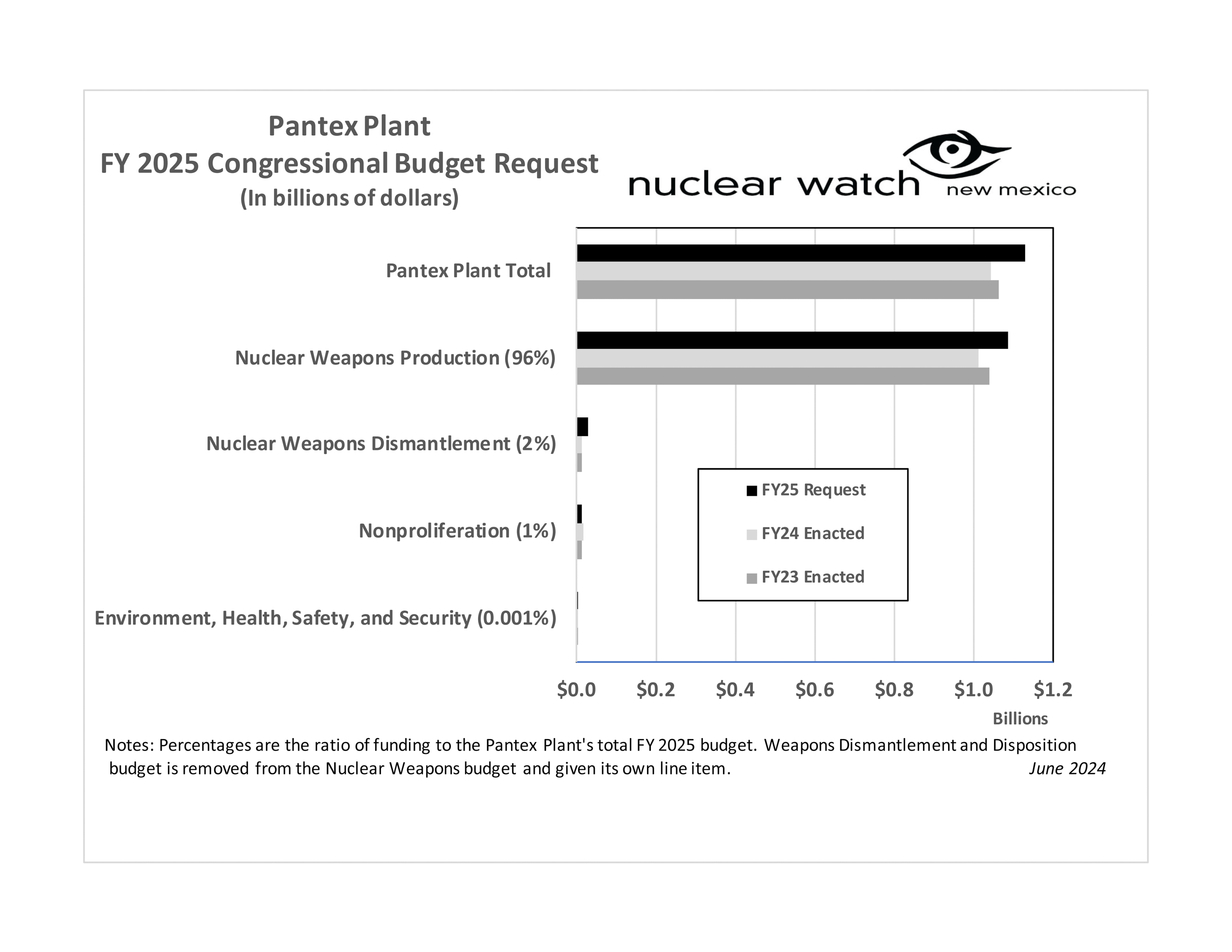

Pantex Lab FY 2025 Budget Request

In February 2024, NNSA administrator Jill Hruby stated, "We have the High Explosives Synthesis and Fabrication Production Facility at Pantex in our sights... The first new contracting action we undertook was separation of the Y-12 and Pantex contracts and the competition for Pantex with updated contract terms and proposal evaluation factors. The Pantex contract will have a five-year base period with three five-year options. A potentially longer overall term for the Pantex contract will put NNSA on the path to planning contract competitions that are spaced further apart. Although not immediately achievable, we would like two years between competitions to help avoid conflicts for key personnel and allow the most robust competition. Since we have eight contracts, if they are spaced two years apart contracts will need to run about 16 years on average. In terms of updated evaluation criteria, the Pantex RFP includes an evaluation factor that places emphasis on technical approaches to mission delivery. The evaluation phase of Pantex proposals is underway..." https://www.energy.gov/nnsa/articles/nnsa-administrator-jill-hruby-remarks-2024-nuclear-deterrence-summit

2023 Performance Evaluation Report:

Operations

Although the majority of operations occur on just 2,000 acres, the Department of Energy owns 10,380 acres at the Pantex Plant itself and another 1,077 acres called Pantex Lake about two miles away. An additional 5,800 acres of land south of the main Plant is leased from Texas Tech University as a safety and security buffer.

Pantex is the principal facility in the U.S. nuclear weapons complex for the handling of nuclear weapons in their entirety. Although there have been no completely new weapon designs assembled since 1991, technicians at Pantex continue to disassemble and reassemble existing weapons in connection with NNSA programs to evaluate, repair, modify, and certify them. Under the Life Extension Program (LEP), Pantex disassembles nuclear weapons and reassembles them using new and in some cases redesigned components. Pantex stores approximately 4,000 plutonium pits as a "strategic reserve" and 14,000 pits in all, including excess pits that are awaiting final disposition. Pantex is currently authorized to store up to 20,000 pits.

Pantex is also responsible for manufacturing, testing, and qualifying explosives and explosive components for NNSA's nuclear weapons programs.

Major Facilities at Pantex

Many of Pantex's buildings are between 30 and 60 years old and were designed prior to the current mission. Although there have been new facilities constructed, the total site footprint has remained near 3 million sq-ft.

Pantex has several numbered functional areas. Zone 12 is the weapons assembly/disassembly area. Operations in its 'Nuclear Explosive Bays' include the complete assembly/disassembly of nuclear weapons containing insensitive high explosives (IHE), the partial assembly/disassembly of weapons containing conventional high explosives (HE) and the testing and storage of tritium reservoirs. 'Nuclear Explosive Cells' provide testing or support facilities for weapons and weapons components that contain special nuclear material. Also in Zone 12 are 'Pit Vaults' that provide temporary staging for weapon components that contain radioactive or special nuclear materials such as plutonium pits, canned subassemblies (the nuclear weapons 'secondaries'), radioisotopic thermoelectric generators, and tritium reservoirs.

Zone 11 has 'Explosives Manufacturing' buildings totaling 113,450 sq-ft that are used to produce the main HE charges for nuclear weapons and to conduct HE research and development. There are also 46 Explosives Staging structures used to store all types of HE and IHE, occupying approximately 63,300 square feet. Key facilities for Testing and Evaluation of both HE and IHE, including test firing of explosives and non-destructive evaluation of explosives, total approximately 68,200 square feet.

The 'Nuclear Staging Facilities' storage magazines are located in the western part of Zone 4. These magazines, originally built for storing conventional munitions, are now used for interim storage of complete nuclear weapons, weapons components and other material. The total storage area is 71,362 square feet. There are also other functional areas in Zone 4 such as an explosives test firing facility and a burning ground for disposing of explosive materials.

The 'Weapons Evaluation Test Laboratory' (WETL), operated by the Sandia Labs, has been located at Pantex since 1966. WETL evaluates weapon subsystems in a laboratory environment in order to detect potential defects in stockpiled weapons.

At the 'Special Nuclear Material Requalification Facility' NNSA plans to use non-intrusive processes to re-certify up to 350 plutonium pits for reuse annually, some of which may be modified before being returned to the stockpile. The Plant itself has boasted how pit reuse is much less expensive and environmentally damaging than the production of new pits.

Pantex in NNSA’s “Complex Transformation”

NNSA's Complex Transformation plan calls for continued use of Pantex for warhead assembly and disassembly and adds some non-destructive surveillance work now done at LLNL. Pantex is also to be the "Center of Excellence" for high explosives production and machining. Category I/II SNM are to be consolidated to Zone 12 so Zone 4 can be closed. NNSA plans to reduce Pantex's security perimeter by 45% and the total building footprint by 25%. NNSA projects that the Plant's workforce level will be reduced by 5% to 10% over the next decade.

NNSA proposes to construct several new facilities at Pantex. A new underground storage facility for plutonium pits is intended to improve security and reduce costs. A new Weapons Surveillance facility for non-destructive weapon and pit surveillance is planned to supplement the existing WETL. In addition, the High Explosive Component Fabrication and Qualification Facility would replace World War II-era facilities. Finally, a new high explosive pressing facility would support the projected workload for the ongoing W76 LEP and pending LEPs (the W78 and W88) over the next 10 years.

Source: Transforming the U.S. Strategic Posture and Weapons Complex For Transition to a Nuclear Weapons-Free World, Nuclear Weapons Complex Consolidation Policy Network, April 2009.

The members of the Nuclear Weapons Complex Consolidation Policy Network include Nuclear Watch New Mexico along with national organizations: the Natural Resources Defense Council and the Project On Government Oversight; Tri-Valley CAREs, near the Lawrence Livermore National Lab; the Greater Kansas City Chapter of Physicians for Social Responsibility, near the Kansas City Plant; and JustPeace of Texas, near the Pantex Plant.