Description and Current Mission

Description and Current Mission

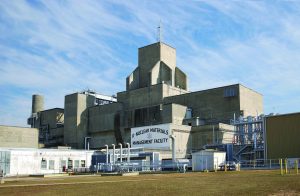

The Savannah River Site (SRS) occupies some 300 sq-mi of south-central South Carolina along the Savannah River between the towns of Barnwell and Aiken. The city of Augusta, Georgia is fifteen miles northwest of the site. The facility is operated by Savannah River Nuclear Solutions, LLC, a consortium headed by Flour Daniel, that includes Fluor Corporation, Newport News Nuclear (a division of Huntington Ingalls Industries), and Honeywell International. It employs about 9,000 people, of which 1,400 support NNSA activities. This huge reservation was established by eminent domain in November 1950 and construction was largely completed by 1956. At its peak, the plant included five heavy-water-moderated production reactors; fabrication facilities for enriched-uranium driver fuel and targets for plutonium and tritium production; a heavy water plant; a tritium extraction, purification, and reservoir-loading complex; and two chemical separation plants. Over a 35-year period, the plant produced all of the tritium and a portion of the plutonium used in the U.S. nuclear weapons stockpile.

Following the end of the Cold War, production of weapons materials ceased and the remaining production reactors were shut down. Tritium purification and loading operations have continued, but the main mission of SRS for the past two decades has been nuclear waste management and environmental cleanup. The cleanup of SRS has already cost tens of billions of dollars and no end is yet in sight.

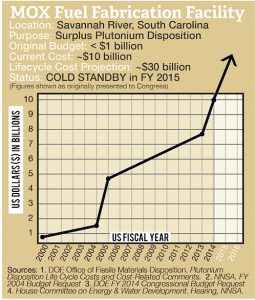

In the late 1990s, SRS acquired a new mission in a non-proliferation deal with the Russians that remains controversial- 'disposition' of 34 metric tons of excess weapons-grade plutonium by converting it into plutonium-uranium mixed oxide (MOX) fuel for use in commercial nuclear reactors. Use of this technology in the civil sector creates inventories of separated plutonium potentially usable in weapons, and thus has significant negative implications for nuclear security and non-proliferation. A Mixed Oxide (MOX) Fuel Fabrication Facility (MFFF) at SRS was initially designed to convert this surplus weapons-grade plutonium into fuel for commercial nuclear reactors, however, due to cost overruns, delays, and changing policy priorities, the project was terminated in 2018 after about $8 billion had already been spent. The original estimate of $5 billion ballooned to over $17 billion by the time of its cancellation.

Instead of the original MOX approach, the Department of Energy has since opted for a "dilute-and-dispose" strategy, which involves down-blending the plutonium for disposal in the Waste Isolation Pilot Plant in New Mexico.

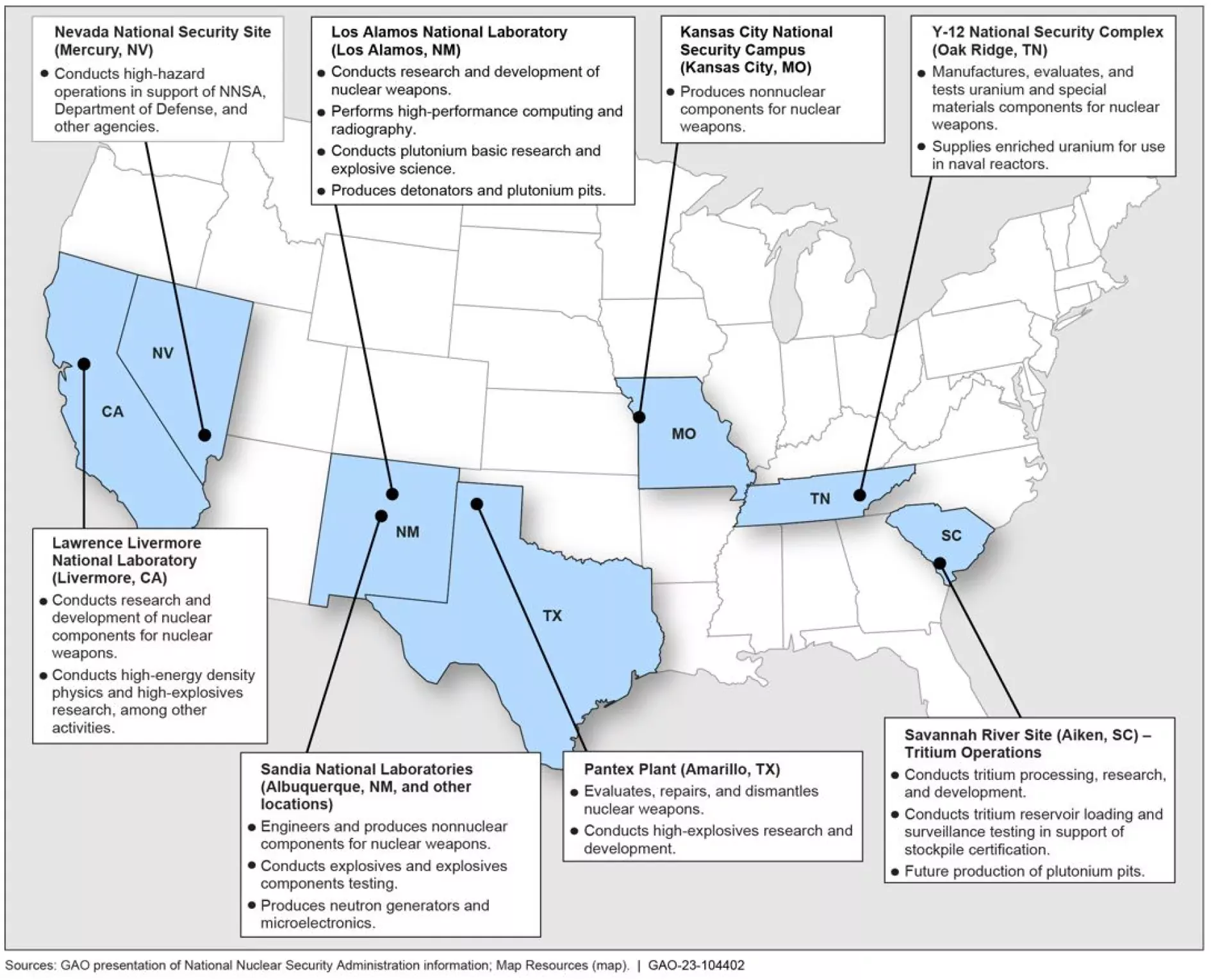

The National Nuclear Security Administration's plans to modernize and expand the site to meet the goal of producing at least 50 plutonium pits annually by 2035 includes transforming the unfinished MOX facility into the Savannah River Plutonium Processing Facility (SRPPF). The infrastructure upgrades required to support this shift in mission has made cost estimates surge significantly. Initial projections have already climbed to over $11 billion, which is far beyond the original estimates for the facility's completion. These expenses are only expected to escalate further, potentially reaching $18 billion to $24 billion when considering the full scope of upgrades.

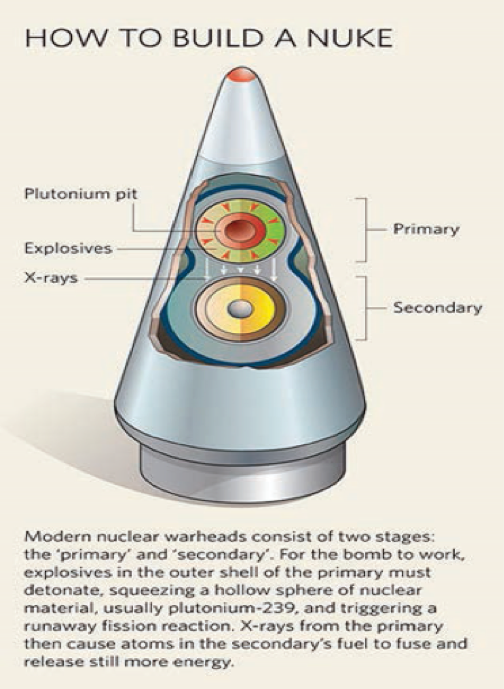

The only other activities at SRS that continue to support the nuclear weapons stockpile are the tritium missions, which employ some 500 workers, and involve extraction, purification, and loading of tritium, a radioactive isotope of hydrogen that is used to 'boost' the performance of the plutonium pit primaries in nuclear weapons.

Savannah River Site Tritium Missions:

- Tritium Supply - extraction of tritium from irradiated target rods and management of the tritium inventory for the nuclear stockpile.

- Nuclear Stockpile Maintenance - loading of tritium and deuterium into reservoirs that are used in the gas transfer system of a nuclear weapon.

- Nuclear Stockpile Evaluation - surveillance of gas transfer systems to assure reliability in the absence of nuclear testing.

- Helium-3 Recovery - recovery of this byproduct of tritium's radioactive decay for use in neutron detectors and various commercial applications.

(Source: National Nuclear Security Administration)

The recently modernized SRS Tritium Facilities consist of an interconnected set of production, processing, support, and administrative buildings located within a 25-acre compound in the H-Area.

The New Manufacturing Building is the reservoir loading and unloading facility. This underground facility has been in operation since 1993 and houses the gas processing systems necessary to remove, separate, and purify hydrogen isotope gas streams (primarily recycled from active or retired nuclear weapons). The desired mix of isotopes is then reloaded into reservoirs destined to be put back into weapons in the active stockpile.

Manufacturing Building No. 3 is primarily used for reservoir finishing, quality assurance activities, and shipping and receiving of reservoirs. This building also houses an analytical laboratory, an inert reservoir loading facility, and other support activities.

The Pressure Testing Facility is the Helium-3 (He-3) processing facility. This facility is nearing the end of its useful life. He-3 processing is scheduled to be relocated into the New Manufacturing Building.

The Material Testing Facility, completed in 2004, contains environmental chambers and ovens, which support the reservoir storage program, and a metallurgical laboratory used for analysis of tritium-contaminated components.

The Reclamation Building is a contaminated machine shop used to reclaim reservoirs that were returned from the field. During this process, the existing fill stem is removed and replaced with a new stem. The reservoir is subsequently inspected and returned to 'War Reserve' status.

Production of tritium now occurs off-site, in 'Tritium Producing Burnable Absorber Rods' (TPBARs) that are irradiated in the cores of TVA's Watts Bar nuclear reactors. The irradiated TPBARs are shipped from Tennessee to the SRS H-Area Tritium Facilities, where they are processed in the Tritium Extraction Facility (TEF), which was completed in November 2006. This facility has two parts- the Remote Handling Building, where tritium is extracted from the TPBARs by heating them in furnaces, and a Processing Building, where the gas is purified before being transferred to the New Manufacturing Building for reservoir loading.

NNSA also performs surveillance on gas transfer systems at SRS. This includes extensive testing and metallographic evaluation. Reservoirs are then reloaded, reinspected, and shipped to either DoD sites for exchange operations involving active stockpile weapons, or to NNSA's Pantex Plant for installation in weapons undergoing Life Extension Programs.

SRS in NNSA's 'Complex Transformation'

Under Complex Transformation, NNSA is planning to continue all current activities at SRS, to transfer tritium R&D activities from other sites to SRS, and to expand operations in support of reactor-based disposition of excess plutonium. NNSA's plan includes building both the PDCF and a new Waste Solidification Building (to treat waste from the MFFF and the PDCF) at SRS.

SRS Stockpiling High-Level Nuclear Waste

Editorial July 13, 2014, Spartanburg, S.C.:

"Too much high-level nuclear waste is already being stockpiled at the Savannah River Site, an ecologically sensitive location that wasn't designed for long-term storage of the dangerous material. So the last thing we should be doing is importing more nuclear waste into the site from Germany. But that's the plan the federal government is working on..." ref: Taking in German waste is the latest federal task for the Savannah River Site

Sources: Transforming the U.S. Strategic Posture and Weapons Complex For Transition to a Nuclear Weapons-Free World, Nuclear Weapons Complex Consolidation Policy Network, April 2009.

The members of the Nuclear Weapons Complex Consolidation Policy Network include Nuclear Watch New Mexico along with national organizations: the Natural Resources Defense Council and the Project On Government Oversight; Tri-Valley CAREs, near the Lawrence Livermore National Lab; the Greater Kansas City Chapter of Physicians for Social Responsibility, near the Kansas City Plant; and JustPeace of Texas, near the Pantex Plant.

In Our Backyard Podcast By Jenn Galler - Blue Ridge Environmental Defense League's (BREDL) Podcast on environmental issues that are right in our backyards

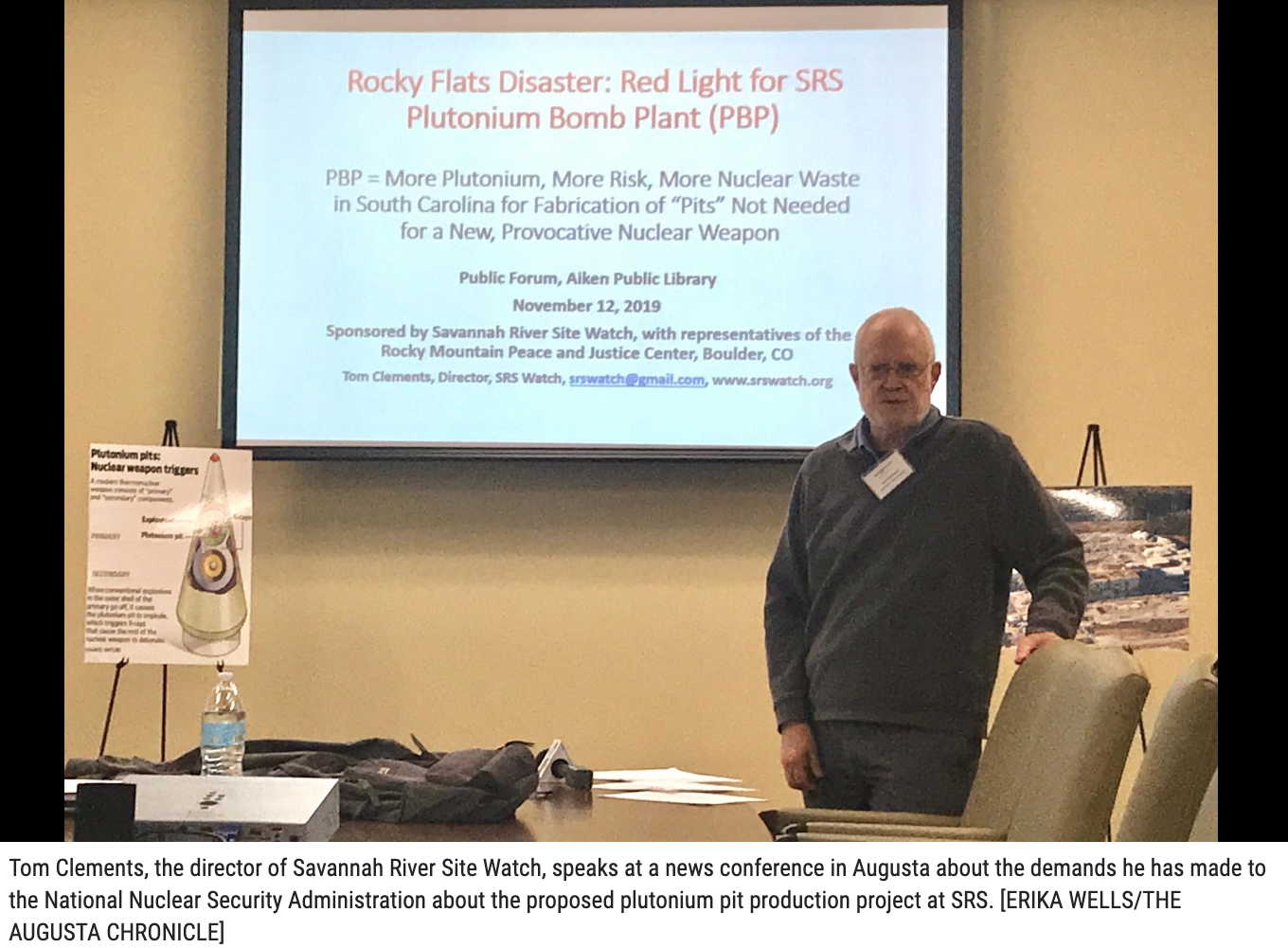

DECEMBER 4, 2020 Tom Clements is Director at Savannah River Site Watch or SRS Watch for short. They are working for the public interest by monitoring activities at the U.S. Department of Energy's Savannah River Site (SRS) in South Carolina and other DOE and commercial nuclear projects in the southeastern U.S. region and beyond & striving to halt proliferation of weapons-usable materials.

The Savannah River Site (SRS) is a nuclear reservation in South Carolina, located on land in Aiken, Allendale, and Barnwell counties adjacent to the Savannah River, 25 miles (40 km) southeast of Augusta, Georgia. The site was built during the 1950s to refine nuclear materials for deployment in nuclear weapons.

It is owned by the U.S. Department of Energy (DOE). The management and operating contract is held by Savannah River Nuclear Solutions LLC (SRNS).

Future plans for the site cover a wide range of options, including host to research reactors, a reactor park for power generation, and other possible uses. DOE and its corporate partners are watched by a combination of local, regional and national regulatory agencies and citizen groups.

With Tom, we discuss what projects SRS is working on, who owns the site and what accountability they have, plutonium fuel and the dangers, and how you can get involved.

Contact and connect with Tom: srswatch@gmail.com

Savannah River Site info: https://srswatch.org/

http://www.bredl.org/nuclear/SRS.htm

https://www.ncsl.org/research/environment-and-natural-resources/savannah-river-site-fact-sheet.aspx

Lawsuit Compels Nationwide Public Review of Plutonium Bomb Core Production

AIKEN, S.C. — Today the National Nuclear Security Administration (NNSA), the semi-autonomous nuclear weapons agency within the Department of Energy, published a formal Notice of Intent in the Federal Register to complete a nationwide “programmatic environmental impact statement” on the expanded production of plutonium “pit” bomb cores. Pits are the essential radioactive triggers of modern...Continue reading→

Historic Settlement Reached in NEPA Lawsuit Over Plutonium “Pit” Bomb Core Production

Nonprofit public interest groups have reached an historic settlement agreement with the Department of Energy’s semi-autonomous nuclear weapons agency, the National Nuclear Security Administration (NNSA). This is the successful result of a lawsuit against NNSA over its failure to complete a programmatic environmental impact statement on the expanded production of plutonium “pit” bomb cores, as...Continue reading→

DOE’s 2037 Deadlines for SRS: Realistic or Illusory?

The Department of Energy’s (DOE) Savannah River Site (SRS) has two major milestones to achieve by 2037. One is legally binding, the other is a commitment that remains negotiable. By Don Moniak, The Aiken Chronicles | November 12, 2024 aikenchronicles.com Surplus Weapons Plutonium DOE is legally bound to removing 9.5 metric tons of surplus military plutonium to...Continue reading→

Searchlight NM: Plutonium just had a bad day in court

In a major decision whose consequences are still being assessed, a federal judge declared that plutonium pit production — one ingredient in the U.S. government’s $1.5 trillion nuclear weapons expansion — has to be performed in accordance with the nation’s strongest environmental law “…The court found that the agencies charged with reviving the nuclear weapons...Continue reading→

Court Rules U.S. Nuclear Weapons Production Plan Violates Federal Law

On September 30, United States District Court Judge Mary Geiger Lewis ruled that the United States Department of Energy (“DOE”) and its semi-autonomous nuclear weapons agency, the National Nuclear Security Administration (“NNSA”), violated the National Environmental Policy Act (“NEPA”) by failing to properly consider alternatives before proceeding with their plan to produce plutonium pits, a...Continue reading→

NNSA Town Hall July 22nd – Hruby: “We have to limit the growth of Los Alamos Laboratory…”

The U.S. Department of Energy (DOE) Office of Environmental Management (EM) Los Alamos Field Office held a Town Hall event hosted by the DOE National Nuclear Security Administration (NNSA) and EM on Monday, July 22, in Santa Fe. The Town Hall was led by NNSA’s Jill Hruby and EM’s Senior Advisor Candice Robertson. The intent according the...

Nuclear Weapons Issues & The Accelerating Arms Race: February 2024

FEDERAL BUDGET NEWS Release of federal FY 2025 budget expected March 11 (it will initially be just topline numbers). Meanwhile on the FY 2024 budget: House and Senate Armed Services Committee authorized funding exceeding Biden’s request, including money for the Sea-Launched Cruise Missile and nuclear warhead (reminder: that the President doesn’t want), plus adding $$...Continue reading→

National Nuclear Security Administration: New Assessments of Major Projects from the Government Accountability Office

National Nuclear Security Administration: Assessments of Major Projects GAO-23-104402 Published: Aug 17, 2023. Publicly Released: Aug 17, 2023. The National Nuclear Security Administration plans to invest over $30 billion in its major projects to modernize the research and production infrastructure supporting the nation’s nuclear weapons stockpile. This is our first biennial assessment of NNSA’s major projects. As...Continue reading→

Top Environment Official Takes Inside Info to Nuclear Weapons Agency, Gets Puny Slap-on-Wrist for Ethical Violation; Governor Should Enforce State Code of Conduct

FOR IMMEDIATE RELEASE, February 8, 2023 | Joni Arends, Concerned Citizens for Nuclear Safety – 505.986.1973 | EmailJay Coghlan – 505.989.7342 | Email Santa Fe, NM – The Department of Energy (DOE) will spend $9.4 billion dollars in New Mexico during this fiscal year 2023, 10% more than the State’s entire operating budget of $8.5...Continue reading→

Independent Government Accountability Office Releases Scathing Report on Expanding Plutonium Pit Production; Pressure Mounts on Los Alamos Lab to Increase Production

FOR IMMEDIATE RELEASE, January 12, 2023 | Jay Coghlan – 505.989.7342 | Email Santa Fe, NM – Today, the independent Government Accountability Office (GAO) released a scathing report entitled NNSA Does Not Have a Comprehensive Schedule or Cost Estimate for Pit Production Capability. The National Nuclear Security Administration (NNSA) and its parent Department of Energy...Continue reading→

Independent Government Accountability Office Releases Scathing Report on Expanding Plutonium Pit Production; Pressure Mounts on Los Alamos Lab to Increase Production

Santa Fe, NM – Today, the independent Government Accountability Office (GAO) released a scathing report entitled NNSA Does Not Have a Comprehensive Schedule or Cost Estimate for Pit Production Capability. The National Nuclear Security Administration (NNSA) and its parent Department of Energy have been on the GAO’s High Risk List for project mismanagement since 1991....Continue reading→

RE: The Santa Fe New Mexican “GAO: Cost, time estimates for making nuclear bomb cores flawed” – Underneath it All is the Nuclear Elephant in the Room: Future Pit Production is Actually Unnecessary.

BY JAY COGHLAN Good article indeed. Kudos to Scott Wyland. But to add to it: The National Nuclear Security Administration (NNSA) cannot do, or rather will not do, good governance 101 for its largest program ever (i.e., expanded plutonium pit production), which is credible cost estimates and schedules. Why won’t NNSA do that? Because of...

Confirmation that SRS Plutonium was taken to DOE’s Pantex Site in Texas

The Defense Nuclear Facilities Safety Board (DNFSB), which conducts oversight of DOE projects, has confirmed that plutonium from SRS was taken to the Pantex site in Texas, for storage. Sounds like it’s being stored in bunkers where plutonium pits (from nuclear weapons) are stored.TOM CLEMENTS SRS Watch | March 8, 2022 srswatch.org It is unclear what...

This is OUR Neighborhood: Expanding the Capacity of New Mexico’s Nuclear Waste Repository Affects Communities across the Country.

The original mission of the Waste Isolation Pilot Plant (WIPP) in southeastern New Mexico had two specific stipulations: it was to be the FIRST and only operating underground nuclear waste repository in U.S; and it is ONLY authorized to take a certain kind of nuclear weapons waste – legacy transuranic (TRU) waste. In December of...Continue reading→

South Carolina Environmental Law Project and Nuclear Watchdogs Virtual Press Conference

Nuclear Watch New Mexico, along with other watchdog groups, has announced a lawsuit against the Biden administration over its expanded production of plutonium cores for the U.S. nuclear weapons “modernization” plans. There has been inadequate environmental review by federal agencies, who have failed to detail potential impacts of the projects around communities in New Mexico...Continue reading→

Virtual Advocacy for “Safety, Security, and Savings” at ANA DC Days:

May 26, 2021 Nuclear Watch New Mexico virtually visited Washington, DC this month to participate in the Alliance for Nuclear Accountability’s “DC Days,” an annual event where organizations from across the nation, whose members are directly affected by nuclear weapons production and the incidental health and environmental consequences, make their voice heard to federal policy...

Notice of Impending Lawsuit to DOE & NNSA Over Nuclear Bomb Core Plans from Environmental Groups

Nuclear Watch New Mexico, as part of a larger coalition of environmental groups, has threatened the federal government with a lawsuit over cross-country plans to produce plutonium pits, the cores at the heart of modern nuclear weapons. A more comprehensive review should have been done on the plans to produce plutonium cores at Los Alamos...Continue reading→

DOE Publishes Reactor Impact Statement

“Given that no clear mission need has been established for the VTR and with an estimated price tag of $3 billion to $6 billion, with completion ranging from 2026 to 2030, it is doubtful if the project will go forward..Just as for other costly, complex DOE projects, the price tag is certain to grow and...Continue reading→

New Aerial Photos Released of the Trio of Failed Nuclear Projects in South Carolina & Georgia: Plutonium Fuel/MOX (Proposed to be Converted into a Plutonium Bomb Plant) and the Vogtle & V.C. Summer Nuclear Reactor Construction Sites

Savannah River Site Watch Columbia, South Carolina https://srswatch.org/ November 30, 2020 Columbia, SC (aka new Nuclear Ground Zero) — Dramatic aerial photos of the massive nuclear construction projects in South Carolina and Georgia have been released by the public interest organization Savannah River Site Watch. The photos of the three failed projects, two of which...

Biden expected to re-examine SC factory

“South Carolina could be left holding the plutonium bag…It’s clear that the plutonium bomb plant at SRS is being driven by contractors and boosters who stand to profit by making South Carolina ground zero for an unacceptable new nuclear arms race that endangers national security and that places our state at environmental risk.” — Tom...Continue reading→

DOE Issues Controversial Decision to Pursue a Plutonium Bomb Plant (PBP) at Savannah River Site (SRS); Inadequate Environmental Review and Lack of Justification for Production of 50 or More “Pits” per Year to Modernize Entire Nuclear Weapons Stockpile Open to Legal Challenge

November 5, 2020 The U.S. Department of Energy (DOE) today issued a formal decision that it will pursue a massive Plutonium Bomb Plant (PBP) at the DOE’s Savannah River Site (SRS) in South Carolina, in order to produce plutonium “pits,” or cores, for nuclear warheads. The provocative decision, which adds fuel to concerns about a...Continue reading→

New study says LANL nuclear pit production could go higher

Jay Coghlan, executive director of Nuclear Watch New Mexico, said he doubted the lab has the “expertise and competence” to produce 80 plutonium pits, “but they’re going to eat up taxpayers’ money.” Coghlan said he’s also concerned about defense leaders refusing to use the thousands of pits stockpiled during the Cold War and instead favoring...Continue reading→